Prompt: Create a functioning prototype to solve a problem you have experienced professionally.

Proposal: A bicycle-powered wood chipper for home garden or small farm use.

Process

Background Research

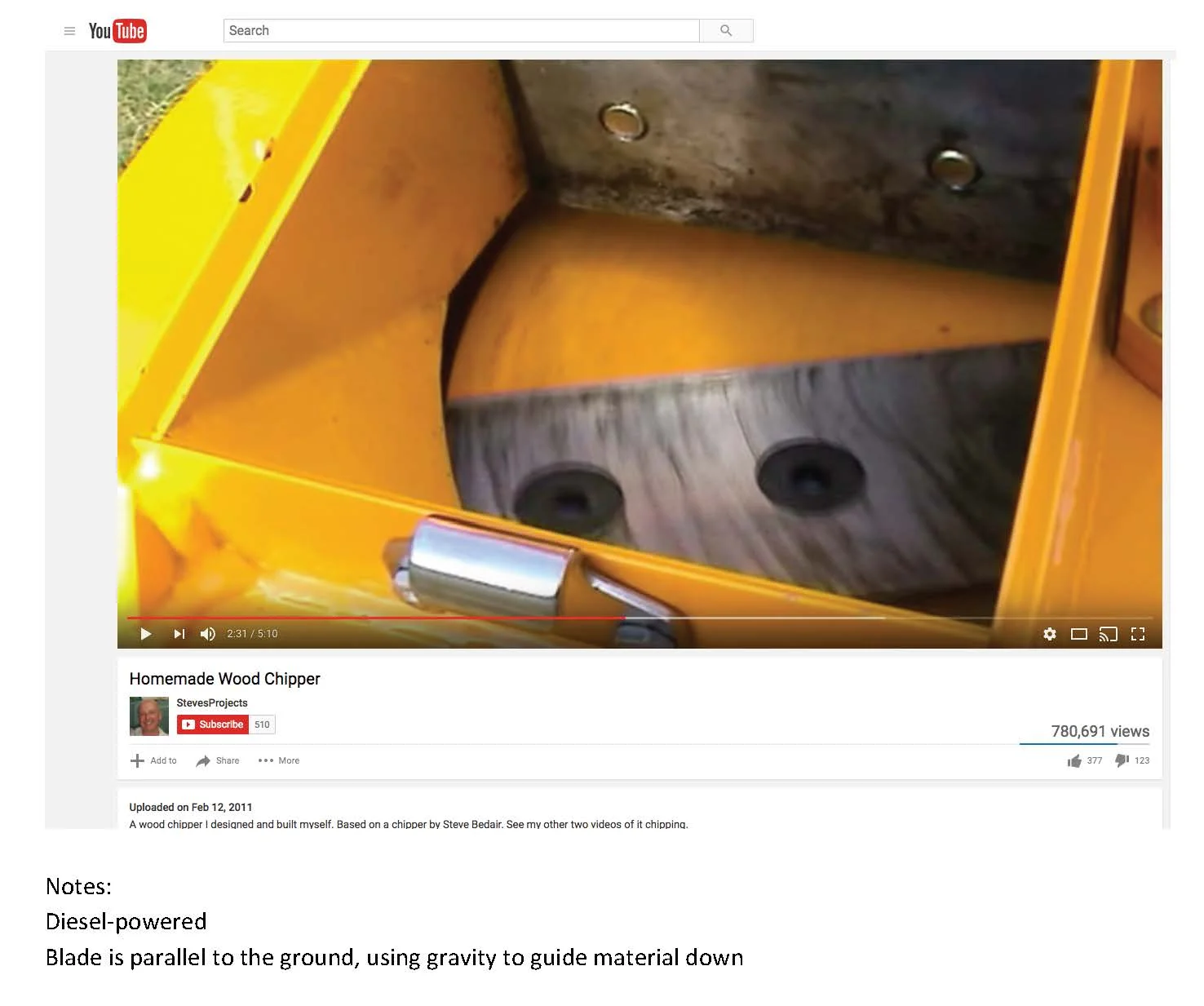

In my work as a farmer and educator, I frequently taught people the basics of small-scale composting but the process is often tricky. Small scale growers often have branches, shrubs, and dead plants that they would like to compost but the materials are too thick and fibrous to break down. I researched what solutions growers have used to address these materials and found people who had built small diesel wood chippers for home use. From these makers, I learned about the essential structure of a wood chipper but knew that my users would prefer a product that did not use fossil fuels. Given my experience with bicycle-powered blenders and crank-powered washing machines, I began to form the idea of a bicycle-powered wood chipper.

Sketch

After buying a bicycle, I began mapping the process to attach the back wheel’s chain to a mechanism that would spin a blade as well as container to hold the blade in proper position and funnel material towards the blade. There would need to a base to hold back of the bicycle at the proper height and the position of the blade container would need to be offset a few inches from the base to allow a dowel to connect the blade and the chain. Overall, I designed a base and a container that were placed on a single board to hold everything in its proper position.

Build

I constructed the base and the blade container out of plywood and based my measurements around a 6-inch blade from a kitchen food processor. The blade container needed to be large enough to hold the blade as well as funnel the chipped material out of the container. The blade would also need to be safely covered from hands feeding material towards it. I created a box with a hinged front and a hopper that could feed material towards the blade while being inaccessible to small hands.

Test

As part of my final presentation, I tested my prototype with the help of a friend. As she pedaled, the chain engaged a dowel holding the blade steady in the wooden box. The blade spun and I fed dried plant material into the hopper. As the material hit the blade, it was chopped into small pieces and lay on the floor of the box before funneling out the side.

Next Iterations

I named my product The Beaver Bike and can imagine selling it as a full product including the bicycle and the attachment for small scale garden use or as an attachment to an existing bicycle. After taking questions from my classmates and guests, I know that the Beaver Bike will need further engineering maintain proper tension between the blade and bicycle chain. Also, a larger, heavier blade could be more powerful in chopping denser material but these blades could make the product heavier and more dangerous to the user.